Core Business - Ammonia Cracking / Hydrogen Production & Power Generation

Innovative Energy Solutions: Ammonia and Hydrogen

Renewable energy sources like solar and wind power are highly sensitive to environmental changes, leading to fluctuations in energy production. As they may not consistently generate energy or meet sudden surges in demand, they are often utilized as supplementary means. For instance, in Australia's vast deserts, where the sun shines brightly, considerable amounts of electricity can be generated using solar power. However, such locations are often remote from populated areas, posing challenges in supplying the electricity generated. Nevertheless, there's a solution: storing the generated electricity in the form of hydrogen. When electricity is needed again, it can be obtained from hydrogen without emitting any harmful substances, including carbon dioxide. This enables us to utilize fluctuating renewable energy sources reliably and safely, paving the way for a more stable and sustainable energy future.

However, hydrogen storage and transportation pose significant challenges. Therefore, a new idea has emerged: converting hydrogen into ammonia, then converting it back to hydrogen when energy is needed. Ammonia has a much higher boiling point compared to hydrogen, making it easier to store as a liquid. Additionally, its density is higher than liquid hydrogen, providing a higher hydrogen content for the same volume. Since there's no need to increase pressure significantly, transportation, storage, and piping become much simpler. Furthermore, the process of decomposing ammonia to extract hydrogen only emits environmentally friendly nitrogen, making it perfectly suited for application in true eco-friendly energy systems.

Ammonia - Hydrogen Business

From 2018 to 2021, CES has been the leading company in a government research project aimed at decomposing and refining ammonia to extract hydrogen. The research and development efforts have been successfully completed, achieving results that exceed the initial goals, with hydrogen purity exceeding 99.97%, residual nitrogen below 100ppm, and residual ammonia below 0.1ppm. Additionally, the performance of the system has been validated through integrated operation for over 100 hours and testing with fuel cells.

1. Ammonia, previously stored as a liquid, is supplied to the reactor as it vaporizes.

2. The burner supplies heat to the reactor.

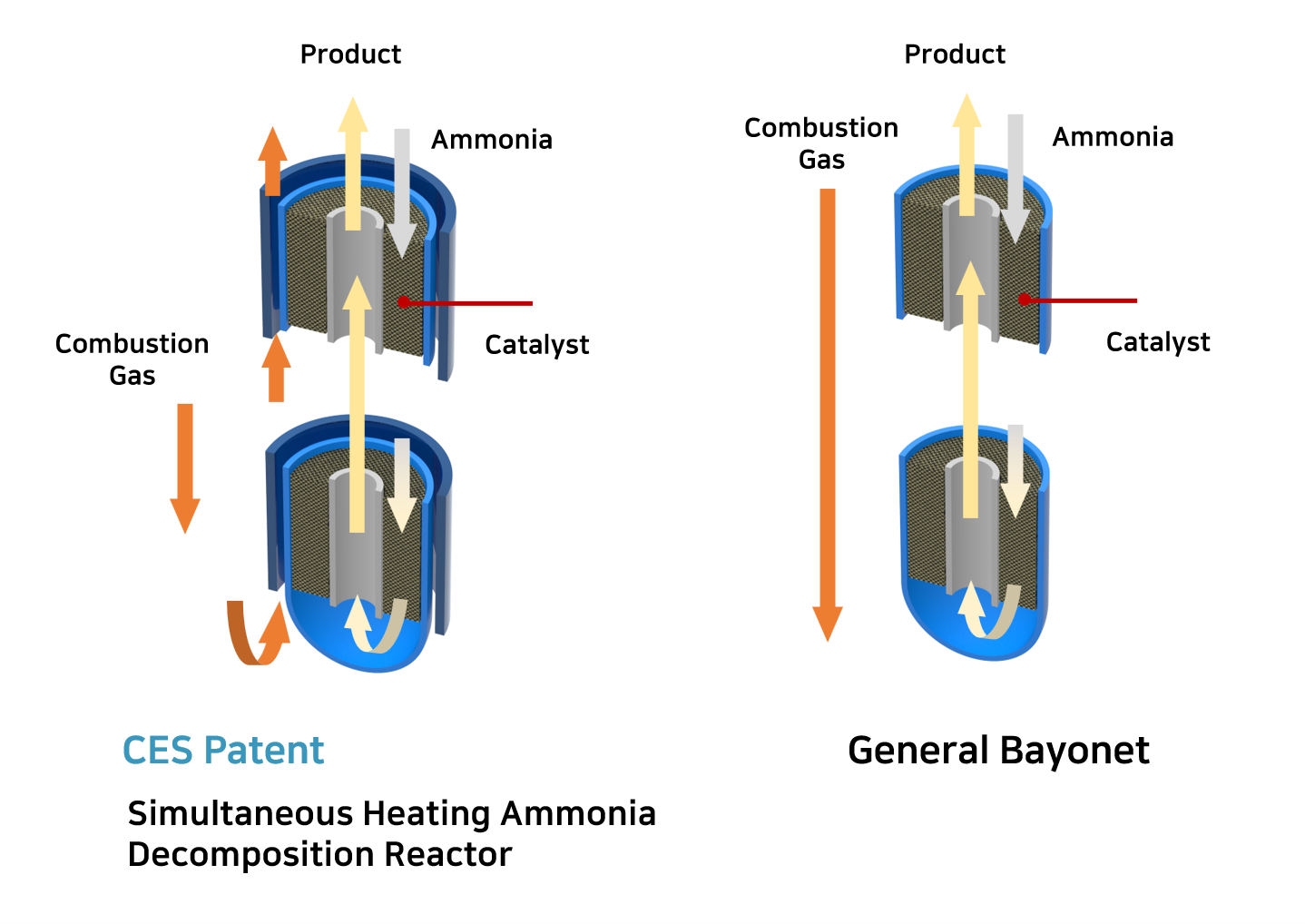

3. Within the reactor, with the assistance of ruthenium or nickel catalysts, ammonia decomposition occurs.

4. The gases exiting the reactor consist of hydrogen, nitrogen, and a small amount of unreacted ammonia.

5. Nitrogen and residual ammonia are removed through PSA or appropriate absorption/filtration.

6. The produced high-purity hydrogen generates electricity in fuel cells.

7. The electrical energy is either used directly or stored in ESS.

Actionable Steps We Can Take

CES is working on developing ammonia-hydrogen-fuel cell packages for various capacities and purposes, especially focusing on smaller power generation facilities. While it would be ideal for all power plants to switch to hydrogen or renewable energy for the environment's sake, the reality is quite different. Currently, there are over 2,400 coal-fired power plants operating worldwide, with over 200 more being built. Therefore, the best approach is to gradually decrease thermal power generation while implementing carbon capture methods to reduce emissions.

Our proposed immediate actionable step is to replace small to medium-sized diesel generators commonly used in outdoor venues, construction sites, small islands, and smart farms with ammonia-hydrogen power generation facilities. Ammonia-hydrogen power generation not only addresses environmental concerns but also offers the advantage of minimal noise and almost no generation of fine dust particles.